|

|

|

|

Soft

Ferrites Soft

Ferrites

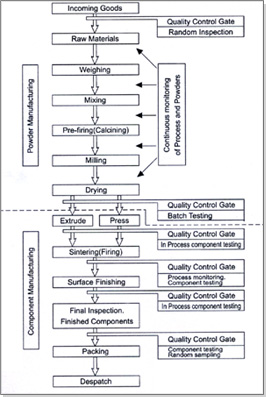

Processing a composed iron oxide mixed

with other major materials such as oxides or carbonates of

either Mn/Zn or Ni/Zn.The basic process can be divided into

four major funtions:

1.Preparation of the powder

2.Forming powder into cores

3.Firing or sintering

4.Finishing the ferrite components

鐵粉芯製作工序

鐵粉芯製作工序為氧化鐵混合其它主要材料例如氧化錳或

氧化鋅,其基本處理步驟可分成4個功能

| 1. |

Powder preparation (粉末準備)。 |

| 2. |

Forming(成型) 使粉末成各種形狀鐵粉芯。 |

| 3. |

Sintering (燒結) 製作鐵粉芯的關鍵,在此階段,鐵粉形成最終的磁性及機構特性。 |

| 4. |

finishing (完成) 燒結完成後,鐵粉芯需要一些完成的操作以符合客戶的需求,例如,研磨氣隙,鏡面研磨,塗裝。 |

Lab

Equipment Lab

Equipment

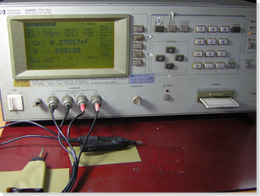

HP 4284 LCR METER to insure

Correct and consistent C-V measurement results with Micromanipulator

probing equipment. In

each case, recommended probe/chuck connection to the HP4284

LCR meter will be explained in detail. Ferrites and

winding products can be measured L and Q value when

incoming or delivery ensure the quality control.

實驗室測試設備

HP-4284 LCR meter 可確認正確及連續性電荷與鐵電記憶結果,用微操作機器設備. 每一個量測,皆有詳細的測量數據,鐵粉芯及其製成品在進出貨時皆須以LCR

meter 量測電氣特性,以確保品質.

|

| |

|

| |

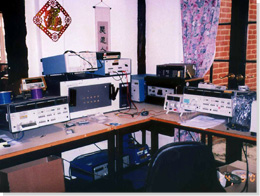

Engineer

Dept Engineer

Dept

Besides research and development, To make sure

the Production Process Control/Quality Assurance, Soft

Ferrite and Finished Products need series of Inspection by

Engineers. Especially the Transformer & Inductor require

a careful test procedure to keep away from Machine burned

or even Explosion.

工程部

除了研究發展, 鐵粉芯及其製品, 需由工程師作一系列檢測,尤其是變壓器,電感器更需要謹慎地測試程序,防止機器燒掉或甚至爆炸.

Lapping

Procedure Lapping

Procedure

Lapping is an post production process used

to decrease the effects of an air gap on mated cores, typically

done on mated cores with material permeabilities over AT5K

in order to achieve the largest AL value for a given material.

The process involves polishing the mating surface of the

core, after grinding, using a slurry based media. This

produces a "mirror-like" finish that requires

careful handling in packaging and in customer assembly.

鏡面研磨

鏡面研磨是鐵粉芯附加製程, 降低配對鐵芯因氣隙研磨的產生的副作用, 運用在配對鐵粉芯,材質AT5K以上,以達成最大的AL值.

此過程使配對鐵芯在配對界面產生像鏡面的表面,當包裝以及在生產線時需要非常小心處理 |

| |

|

| |

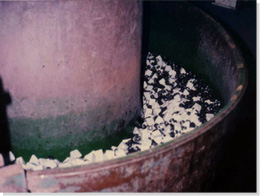

Tumbling

Procedure Tumbling

Procedure

One of the ferrites Finishing process,Development of Edge

Radius - tight control of the tumbling operation for toroids,beads,

and baluns, is necessary in order that a sufficient radius

is developed along with chip and crack free cores.

翻攪程序

鐵粉芯完成工序之一步驟,為了防止鐵粉芯碎裂,鐵粉芯經過翻攪過程,使尖銳邊緣發展成導角形態.

Coating

Procedure Coating

Procedure

Coating of toroids is done after tumbling to enhance dielectric

resistance,reduce edge chip,and provide a smooth winding

surface. Among the choice of coatings are nylon, epoxy

paint and parylene, The nylons and epoxy paints typically

need a minimum coating thickness of .005" to ensure

uniform protection. Because of the restriction, they are

used mainly on toroids with outer diameters of .500" or

greater. One advantage of these coatings is that the color

can be varid for core material identification without stamping.

parylene is a colorless coating used on toroids with outer

diameters less than .500" due to the high cost of

material.

塗裝

翻攪程序後,進入塗裝程序,加強非導電性的阻抗,降低邊緣碎片,提供平滑表面以利繞線,塗裝可選擇 nylon,epoxy

paint,parylene. Nylon and epoxy 塗裝表面厚度,標準為最薄0..005”,確保統一的保護層,因為有一些限制性,主要運用在塗裝外徑為0.500”以上的環型鐵芯.

不同顏色的塗裝的一個好處,是可經由顏色辨識鐵粉芯材質,不必使用戳印. Parylene 塗裝使用在外徑0.500”以下的環型鐵芯,

因為 parylene 塗裝的成本很高. |

| |

|

| |

Hi-Pot test Hi-Pot test

Hi-Pot test is a contraction for high potential High Voltage testing. It

is basically sending high voltage through a wire to test the strength of the

insulation, It is a basic form of Voltage Withstand Testing, Die

Electric Testing as well as Insulation testing for Core and winding core.

高壓絕緣測試

高壓絕緣測試是高伏特電壓測試的其中一種,基本上透過一條線路,送出高伏特電壓去測試絕緣強度. 這是一種阻擋電壓測試,模具電器測試以及絕緣測試的基本形態,測試鐵粉芯及其加工繞線製品. |

| |

|

| |

Winding

procedure Winding

procedure

Many Cores need to be wound by wires such as copper wire in

order to be utilized and plug in the positions which machine

is designed. Transformer, Inductor, Filter different kinds

of applications are broadly used to implement many funtions.

繞線製程

設計儀器設備使用鐵粉芯往往需要作繞線加工,例如繞銅線加工,各種不同的鐵粉芯加工製成品,例如變壓器,電感器,濾波器廣汎地被運用在各種功能.

Production

line Production

line

winding production line: Efficient and unified working procedure

prevent the error occur to be a non-stopped production

at the accuate time. Mass production is based on smooth

operation of production line.

生產線

統一的有效慮工作程序,避免錯誤發生,在準確的時間內,不斷的製程.量產植基於需要平順操作的生產線. |

| |

|

| |

Package Procedure Package Procedure

Vacuum Package : Pack Ferrites Core to Keep away from

the Core decoating and ensure the chip or crack free of ferrite

core. In order to deliver under High Quality, It is necessary

to do this procedure.

真空包裝製程

鐵粉芯真空包裝可避免塗裝脫漆和鐵粉芯在運送當中易產生的碎片與斷裂.為了確保高品質出貨,真空包裝製程是有必要的. |

| |

| |

|

|